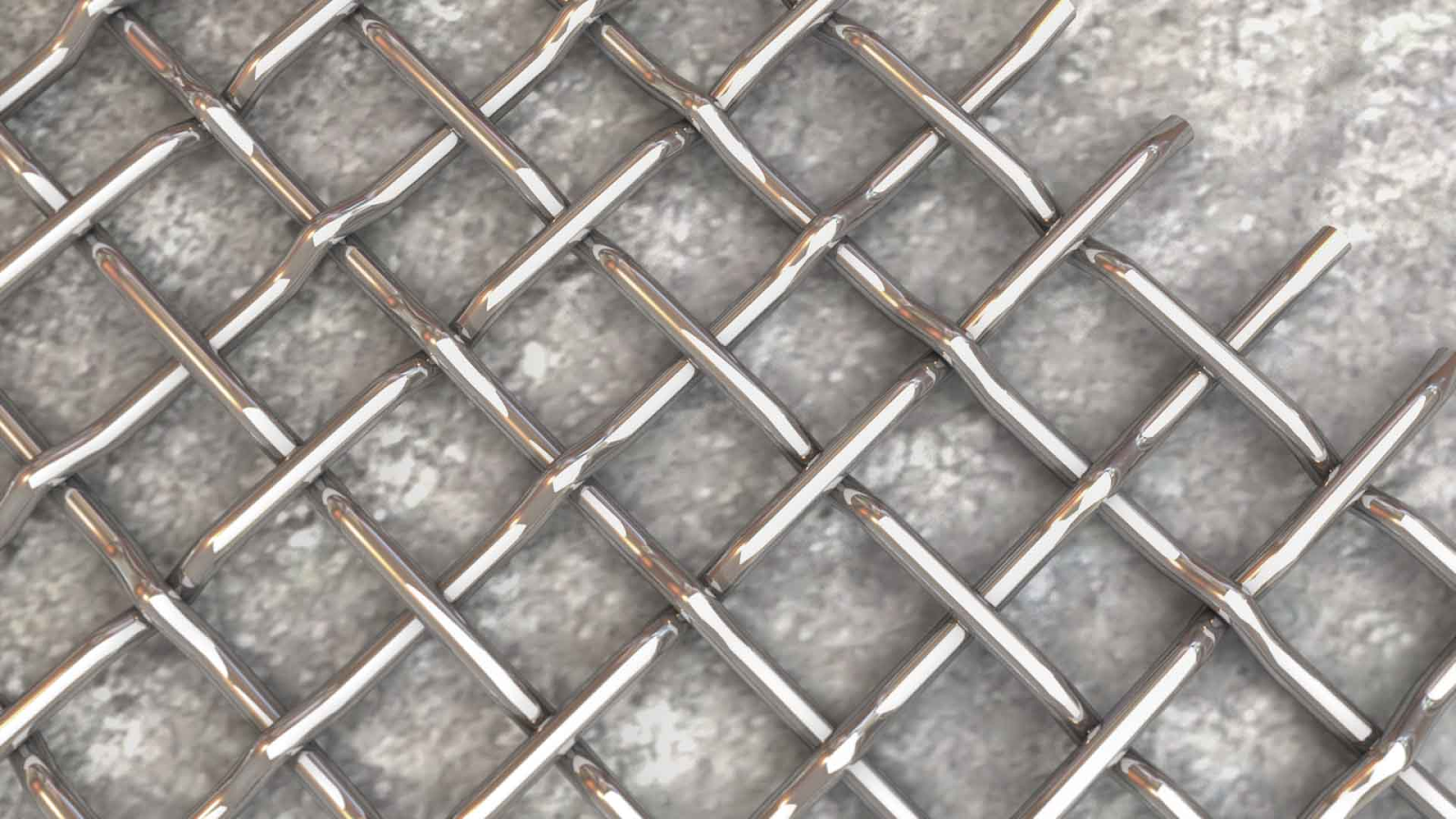

Custom woven wire mesh is a versatile material used in many industries, from construction and manufacturing to agriculture and home projects. Unlike standard mesh products, custom woven wire mesh is made to meet specific needs, including size, thickness, and pattern.

Investing in high-quality custom mesh may seem like an extra step, but it offers long-term benefits that make it worthwhile. Businesses and homeowners alike can save time, money, and effort by choosing mesh that is designed for their exact purpose.

Precise Fit for Every Project

One of the main reasons to invest in custom Woven Wire mesh is that it fits perfectly with your project requirements. Off-the-shelf mesh often comes in standard sizes that may not suit your design. Custom mesh allows you to choose the dimensions, wire diameter, and weave style, which ensures that the material meets your specific needs.

This precision reduces waste and prevents problems during installation. Whether you are building a filtration system, a protective screen, or a decorative structure, custom mesh guarantees the right fit.

Better Durability and Strength

Custom woven wire mesh is designed to last longer and handle more stress than standard mesh. Manufacturers can select stronger metals, tighter weaves, or thicker wires based on how the mesh will be used. This customization increases durability and reduces the risk of damage from heavy loads, weather conditions, or frequent use.

When you invest in custom mesh, you avoid the frustration of replacing worn-out materials, which saves money in the long run. Strong, reliable mesh also improves safety in industrial and construction settings.

Enhanced Efficiency in Use

Using custom woven wire mesh can make your work more efficient. For example, in filtration or separation processes, the right mesh size ensures faster and more accurate results. In construction, a mesh that fits perfectly reduces the need for cutting, trimming, or adjustments, saving time and effort.

Custom mesh can also reduce energy or material waste because it is designed to perform optimally. Investing in mesh that works efficiently helps your projects run smoothly and meet deadlines without unnecessary delays.

Adaptability to Different Environments

Another advantage of custom woven wire mesh is its adaptability. Mesh can be designed to withstand harsh environments, including high temperatures, moisture, or chemical exposure. By choosing the right material and weave, you can ensure the mesh performs well in industrial, outdoor, or specialized settings.

This flexibility makes custom mesh ideal for applications ranging from agricultural fencing to heavy machinery protection. It provides peace of mind knowing that the material will not fail under specific conditions.

Cost-Effectiveness Over Time

Although custom woven wire mesh may have a higher upfront cost, it often proves more cost-effective in the long term. By reducing waste, increasing durability, and improving efficiency, custom mesh lowers maintenance and replacement expenses.

Businesses can complete projects faster and with fewer resources, while homeowners enjoy lasting results with minimal effort. The long-term savings make investing in custom mesh a smart decision that balances quality and affordability.

Conclusion

Custom woven wire mesh is more than just a building material. Its precision, strength, efficiency, adaptability, and cost-effectiveness make it a valuable investment for any project. Choosing custom mesh ensures your work is safer, more reliable, and better suited to your needs.

Whether for industrial use, construction, or home projects, custom woven wire mesh delivers lasting benefits that standard products cannot match. Investing in it today can save time, money, and stress in the future.